Energy water waste treatment

Energy plays an essential role in our lives and has a profound impact on the world. It fuels nearly every aspect of our daily activities – from powering our homes, industries, and transportation, to supporting agriculture, technology, and healthcare. However, the sources and methods of energy production can have significant environmental impacts. Fossil fuel-based energy generation contributes to air pollution, climate change, and habitat destruction. On the other hand, renewable energy sources like solar, wind, and hydropower offer cleaner alternatives, reducing our carbon footprint and helping mitigate climate change. Hence, transitioning towards sustainable energy solutions is crucial for the world’s future, affecting every aspect of society from environmental health to economic growth and social equality.The energy sector, while critical to powering our world, presents significant challenges in terms of wastewater management. Processes such as hydraulic fracturing, cooling of power plants, and refining of fuels produce wastewater loaded with heavy metals, chemical contaminants, and thermal pollution. Traditional treatment methods often fail to adequately remove these pollutants, leading to environmental degradation, regulatory issues, and public health risks.

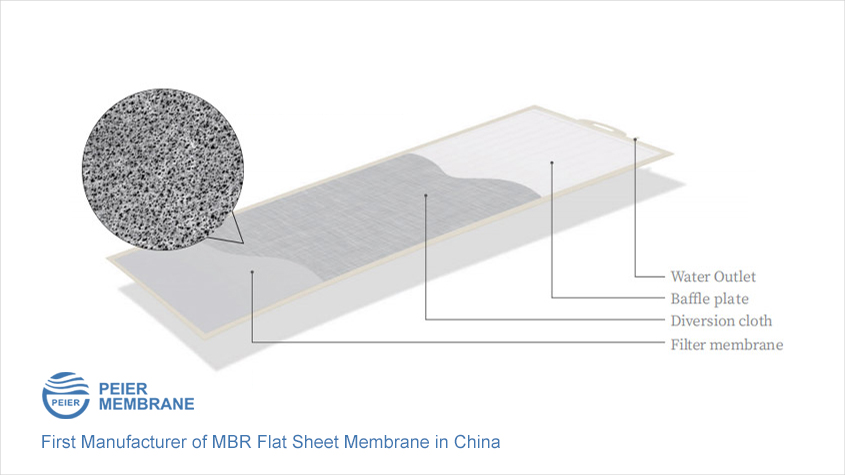

Imagine an energy sector where wastewater is efficiently treated, reducing environmental impact, adhering to regulatory standards, and potentially reusing water within processes. This scenario envisions the use of advanced technology, like flat sheet membrane systems, which effectively remove a wide range of contaminants and can handle the high volumes of wastewater typical in the energy industry.

Energy production exacerbates wastewater problems, challenging the industry to manage contamination from chemical pollutants and thermal discharges effectively.

The journey from the present challenges to a more sustainable future lies in leveraging advanced wastewater treatment technologies like flat sheet membrane systems. These systems provide a physical barrier to separate pollutants, allowing clean water to pass through while leaving contaminants behind. By adopting such technology, the energy industry can effectively manage its wastewater, mitigate environmental impact, achieve regulatory compliance, and move towards a more sustainable operation.