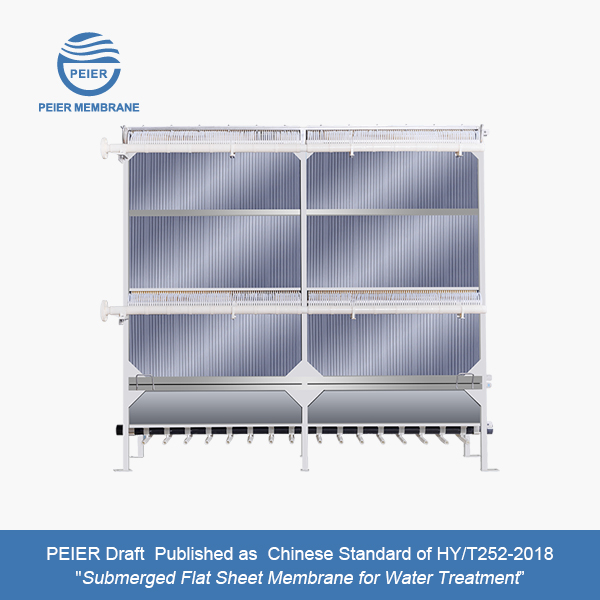

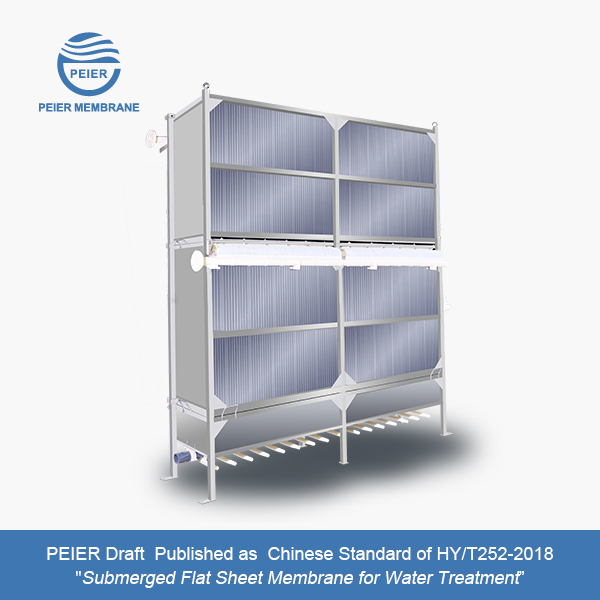

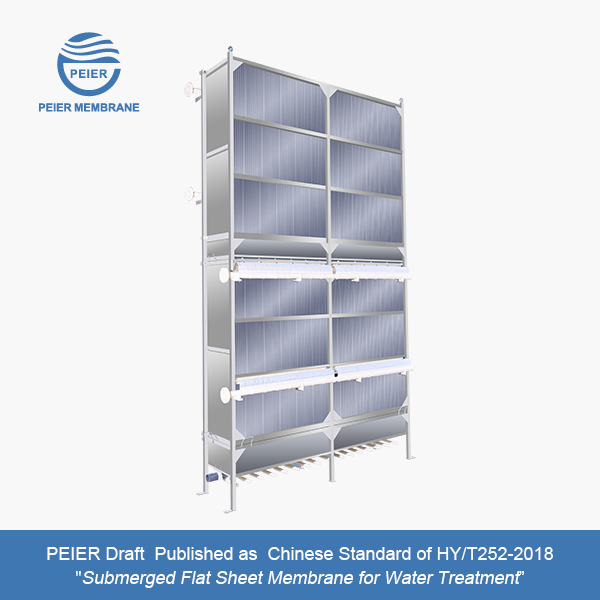

Flat Sheet Membrane Module-Module-Double Nozzle

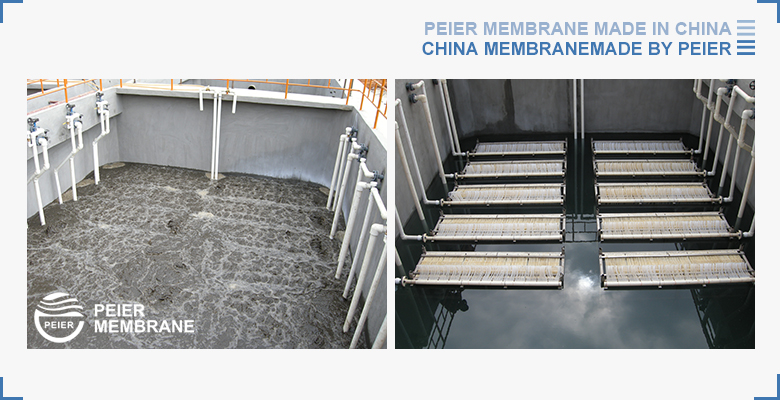

Peier MBR flat membrane has been widely used in industrial wastewater treatment and reclaimed water reuse projects at home and abroad, including medicine, mining, electronics, chemical industry, washing, large-scale municipal wastewater reuse projects.

Description

Module-Double Nozzle

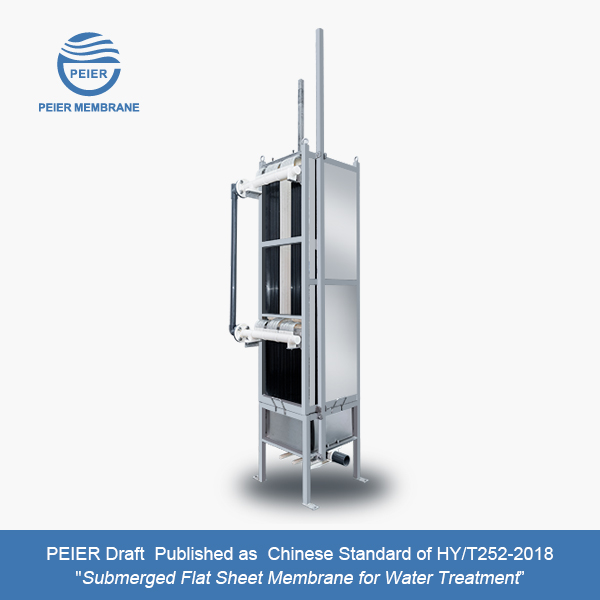

- Unique mechanism structure

- Module upper port extraction and insertion assembly

- Integrally encapsulated side plate

Technical characteristics

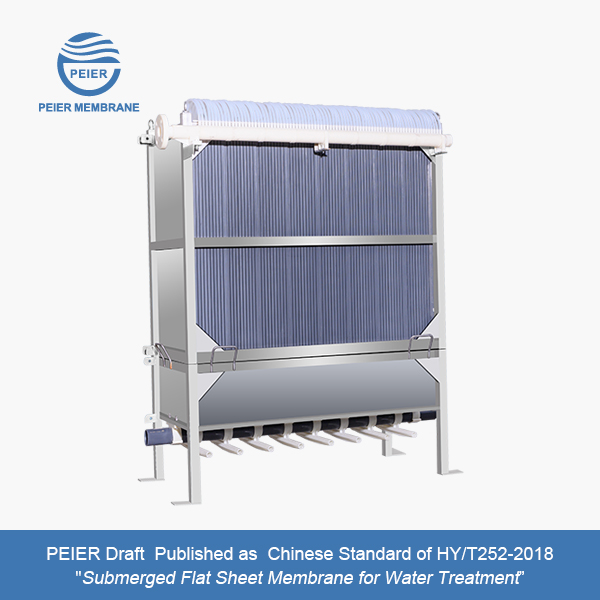

Select 1.5m² Double Nozzle MBR Flat Sheet Element:

● Effective area of 1.5m² Membrane element;

● Two water outlet nozzles are set up at the top and bottom of the side to slow down the vacuum gradient attenuation of high upper and lower dimensions;

● Balance the membrane separation load and greatly improve the separation efficiency;

● Extend the cleaning cycle and reduce the cleaning frequency;

● Guide convex rail is set at the water outlet nozzle side to protect the water outlet at the same time;

The module adopts Peier’s unique and advanced double water outlet flat membrane upper and lower extraction and insertion structure. The socket of the flat membrane slot is located at the top of the assembly frame, and the guide convex rail is clamped into the slot. The flat membrane is inserted from top to bottom, which continues the conventional assembly method, and the maintenance of membrane components is faster and convenient.

The side plate adopts an integrated special slot plate, which is packaged as a whole, greatly improving the effect of aeration scouring the membrane surface.

Structure characteristics

Membrane plate positioning strip with patented technology:

● The wedge-shaped tooth mouth of the upper pressing strip is clamped between the membrane element and the membrane element to eliminate the micro deformation and prestress of the membrane element.

● The relatively added lower pressure strip plays a good role in positioning and vibration isolation of membrane elements, so that the vertical aeration can flush the membrane surface evenly.

MBR Module Table:

Size Unit: mm

| Type | Effective membrane area(m²) | Number of membrane elements | A | B | C | D | E | M | G | H |

|---|---|---|---|---|---|---|---|---|---|---|

| PEIER150II-20 | 30 | 20 | 386 | 606 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-30 | 45 | 30 | 534 | 754 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-40 | 60 | 40 | 682 | 902 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-50 | 75 | 50 | 830 | 1050 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-60 | 90 | 60 | 978 | 1198 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-70 | 105 | 70 | 1126 | 1346 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-80 | 120 | 80 | 1274 | 1494 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-90 | 135 | 90 | 1422 | 1642 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-100 | 150 | 100 | 1570 | 1790 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-110 | 165 | 110 | 1748 | 1968 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-120 | 180 | 120 | 1896 | 2116 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-130 | 195 | 130 | 2044 | 2264 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-140 | 210 | 140 | 2192 | 2412 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-150 | 225 | 150 | 2360 | 2580 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-160 | 240 | 160 | 2508 | 2728 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-170 | 255 | 170 | 2656 | 2876 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-180 | 270 | 180 | 2804 | 3024 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-190 | 285 | 190 | 2952 | 3172 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PEIER150II-200 | 300 | 200 | 3150 | 3370 | 248 | 604 | 794 | 600 | 2380 | 2470 |

Recommended Products

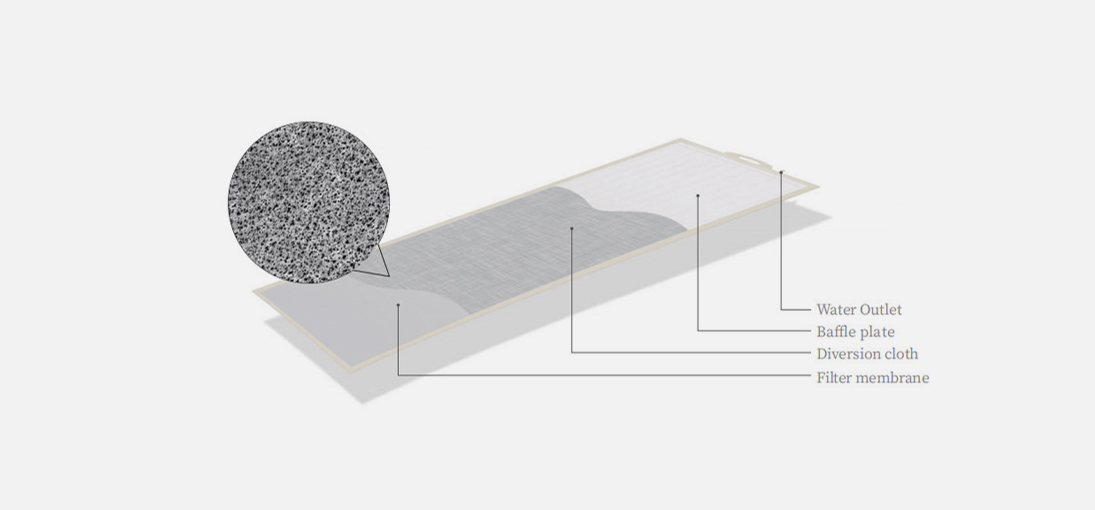

Membrane Element Composition

- Water Outlet

- Bffle Plate

- Diversion Cloth

- Filter Membrane

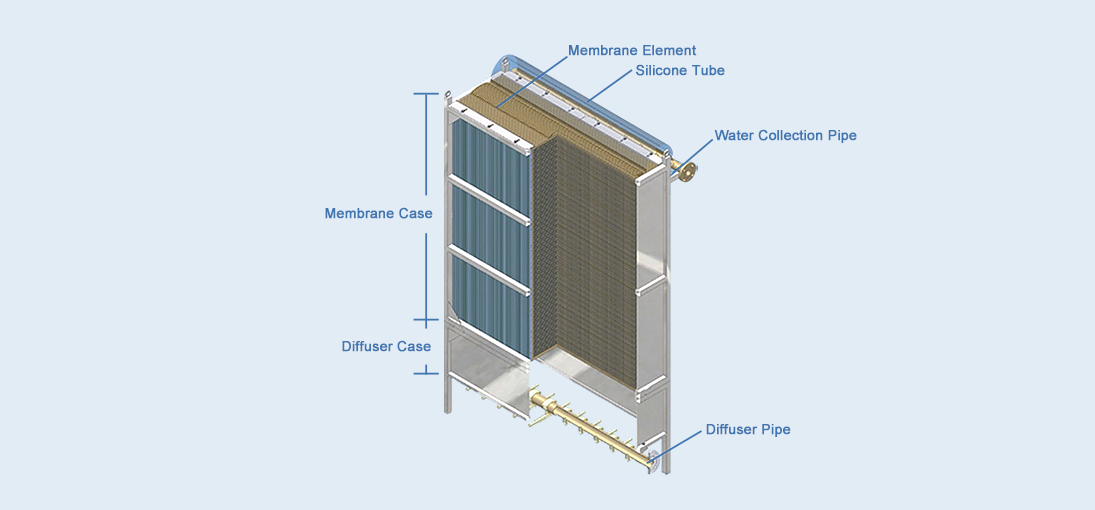

Membrane Modules And Their Components

- Membrane Cartridge

- Silicone Tube

- Water Collection Pipe

- Membrane Case

- Diffuser Case

- Diffuser Pipe

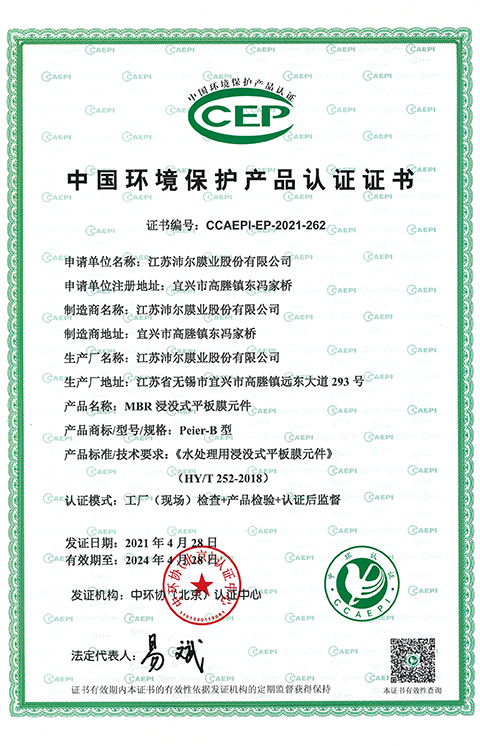

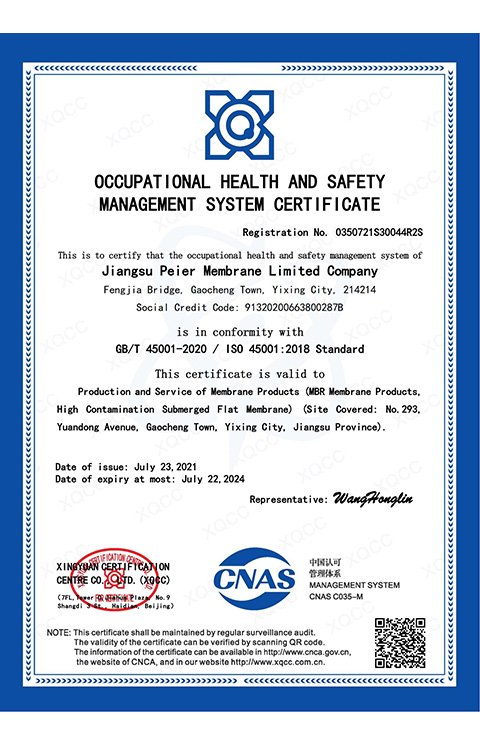

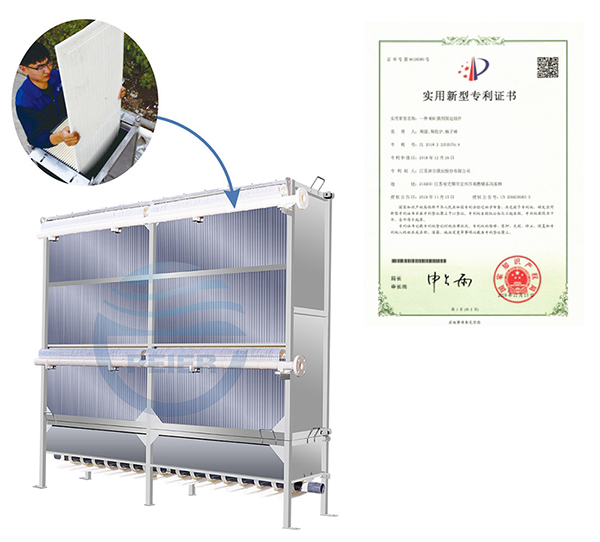

Our Cetificate

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

> Intellectual property management system certificate R&D, production and sales of MBR flat membrane elements and MBR flat membrane components.

> CEP Cetificate of China

> ISO 9001 System Certificate Quality management system certificate

> ISO 9001 System Certificate Occupational health and safety management system certificate

> ISO 9001 System Certificate Environmental management system certificate

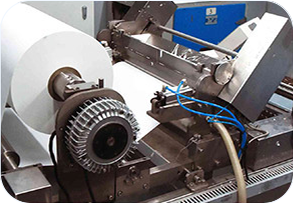

How We Work

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

1. Blending →

2. Scraping →

3. Cleaning →

4. Cutting →

5. Oiling/Drying →

6.Membrane Assembly →

7. Stock Packing →

8. Module Assembly →

Case Study

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

Dos Santos International Airport (Angloa) 500 m3 /d

Kunming Institute of Metallurgy Waste Water Project

5000 m3 /d

Service Support

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

Contact With Us

What they’re talking about our service